Back kart setup

3 TIPS FOR THE BEST…

BACK KART SETUP

A kart is one of the few sporting vehicles without suspension or differential. These features make karts a reference point in Motorsport from the point of view of simplicity.

Apparent simplicity, because over time designers and tuners have found multiple solutions to vary the set-up depending on the type of tyre, track and atmospheric conditions.

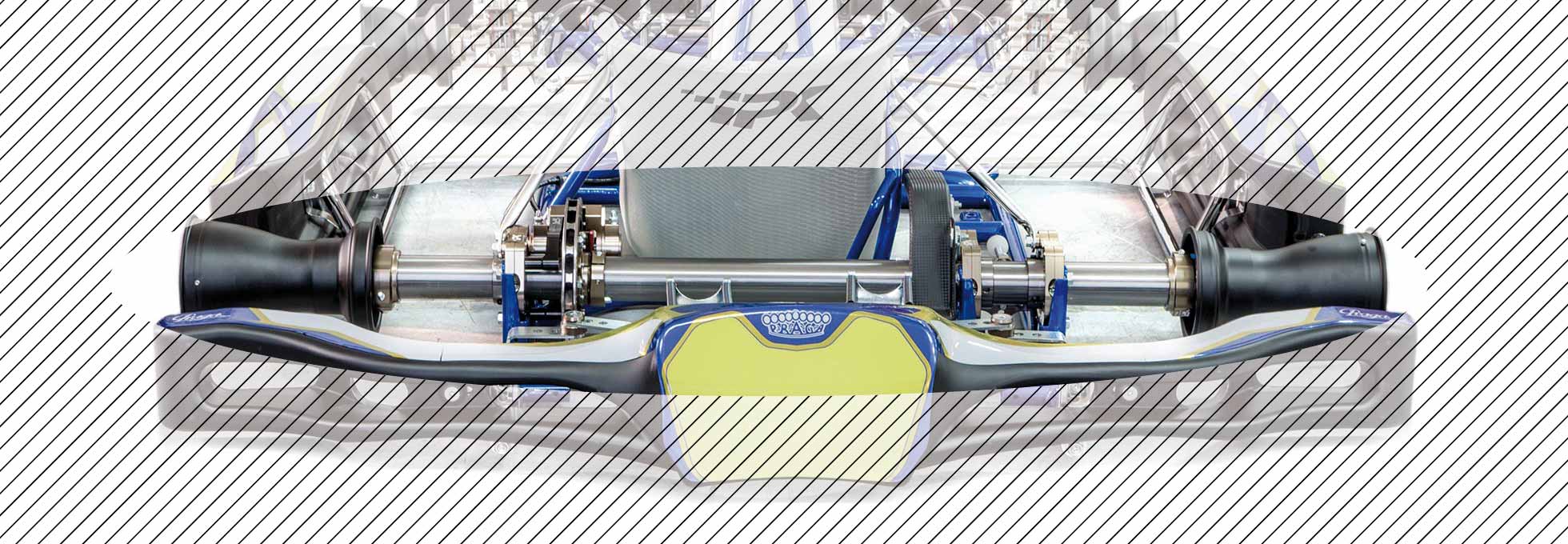

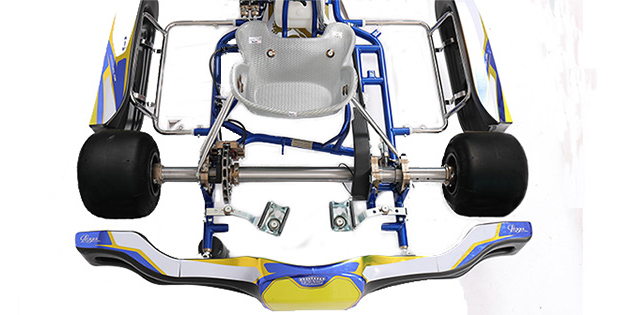

By analyzing the back of the karts manufactured by IPKarting, you will find different solutions to vary the set-up: rear track, axle hardness and hubs.

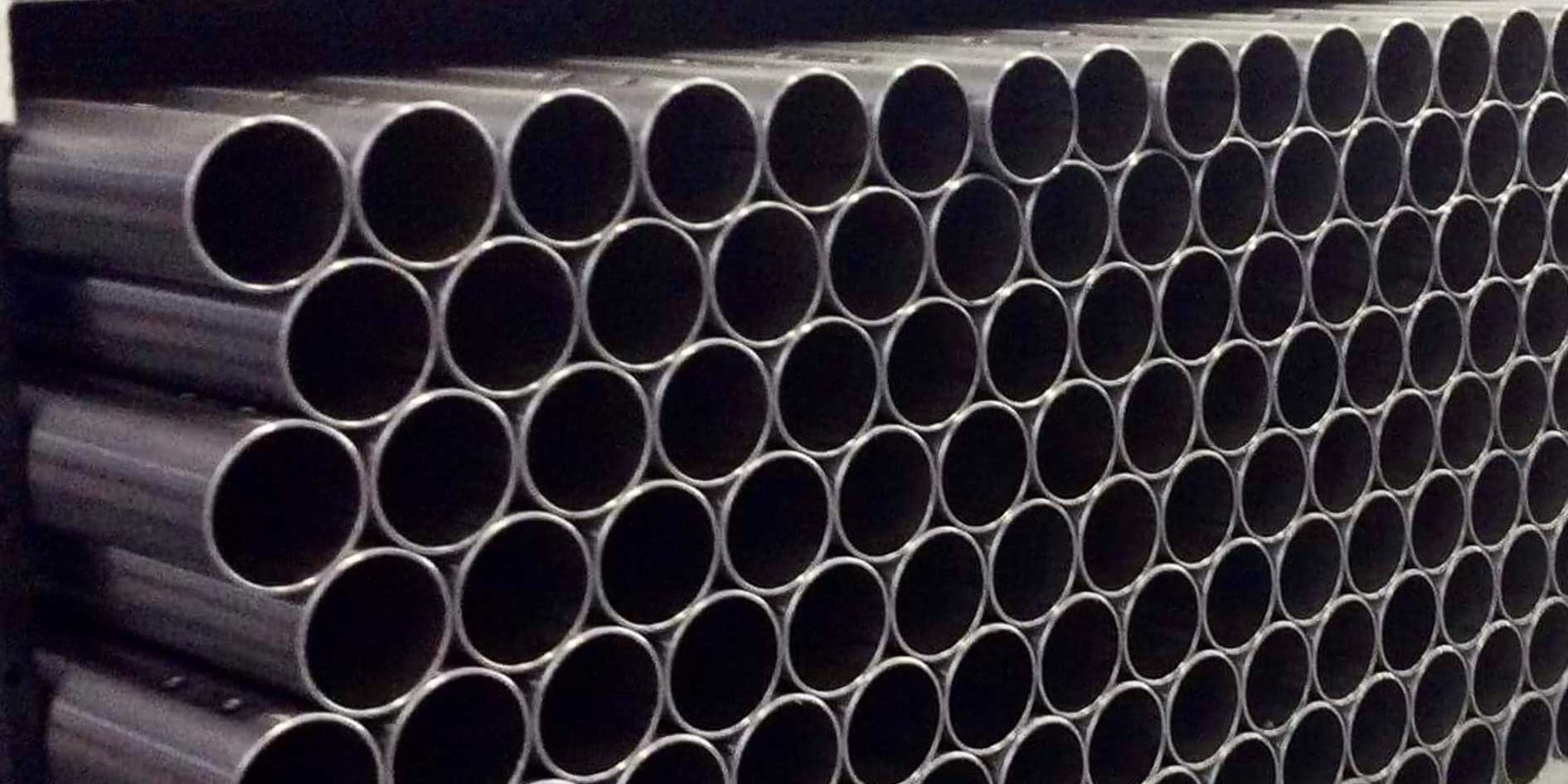

AXLE

The axle is one of the elements that most affects the setup. In practice it’s a bit like changing camber and caster angles, as well as the rigidity of the stub axles, all at once.

In general it can be said that a rigid axle results in greater grip at the rear, thus giving an chassis that is basically subject to understeering, with good half way speeds, and on bends, thanks to excellent traction.

A less rigid axle gives you lose grip and traction, but it helps when approaching bends because the chassis is freer at the rear, slides more but in a much more progressive and controllable way.

LESS RIGID AXLE

If you use a less rigid axle, the behaviour changes on bends. Since it will bend more, the axle will be slightly more parallel to the asphalt than with a rigid axle, with a lower lifting of the inner rear wheel. In addition, the supporting wheel will be flatter to the ground and even the tread will be more stressed on the inside. Since the axle will slip due to the vertical forces, the distribution of the axle will move more to the two front wheels.

MORE RIGID AXLE

With greater rigidity, the axle, which generally flexes most in the area between the supporting tyre and the outer bearing, will tend to do so but only slightly. As mentioned, on a bend, the axle will lean towards the asphalt: the inner rear wheel will rise, while the outer backrest will be crushed to the ground due to the sum of the weight and centrifugal force, so the load will be shifted on the supporting back wheel.

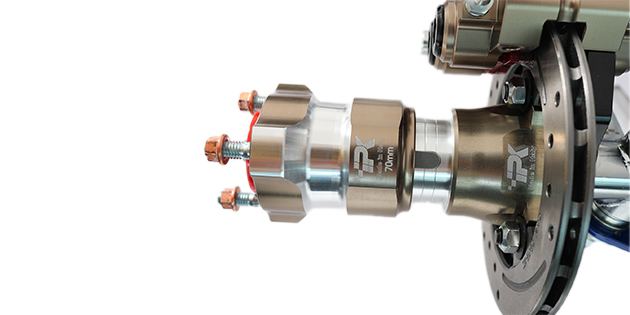

HUBS

If you use a less rigid axle, the behaviour changes on bends. Since it will bend more, the axle will be slightly more parallel to the asphalt than with a rigid axle, with a lower lifting of the inner rear wheel. In addition, the supporting wheel will be flatter to the ground and even the tread will be more stressed on the inside. Since the axle will slip due to the vertical forces, the distribution of the axle will move more to the two front wheels.

MAGNESIUM HUBS

They are more rigid than aluminium, while maintaining a more uniform rim temperature, which means less wear on the tyres.

Magnesium therefore “frees” the set-up more, so in dry track conditions it is the ideal choice for competitiveness.

ALUMINUM HUBS

The length of the hubs is a parameter to be assessed along with the type of axle that is mounted depending on the required configuration.

The hubs, which can be of different lengths, vary the axle’s flexion length: the longer they are and the shorter the free part of the axle that can bend. Vice versa, the shorter they are the more the axle bends.

REAR TRACK

The rear track changes by moving the hubs on the axle and determines, along with the front track, much of the setup. It usually has maximum values (140 cm for OK and KZ classes), but can be decreased in case of very low grip, for example on wet circuits.

A track set to its maximum width gives “freer” kart handling that helps drivers take bends, since the kart slips in a controlled manner that facilitates driving around the bend.

With a narrow track on the rear on a dry track, the kart is more tied to the rear, so the car does not slip very much on bends, further pushing towards the front, causing a rise in temperature and a relative high wearing of the tyre. With a wet track, the narrower rear track helps to partially recover the grip lost on the asphalt.