The new RBS.V2 brake system

NEED TO KNOW

THE NEW RBS.V2 BRAKE SYSTEM

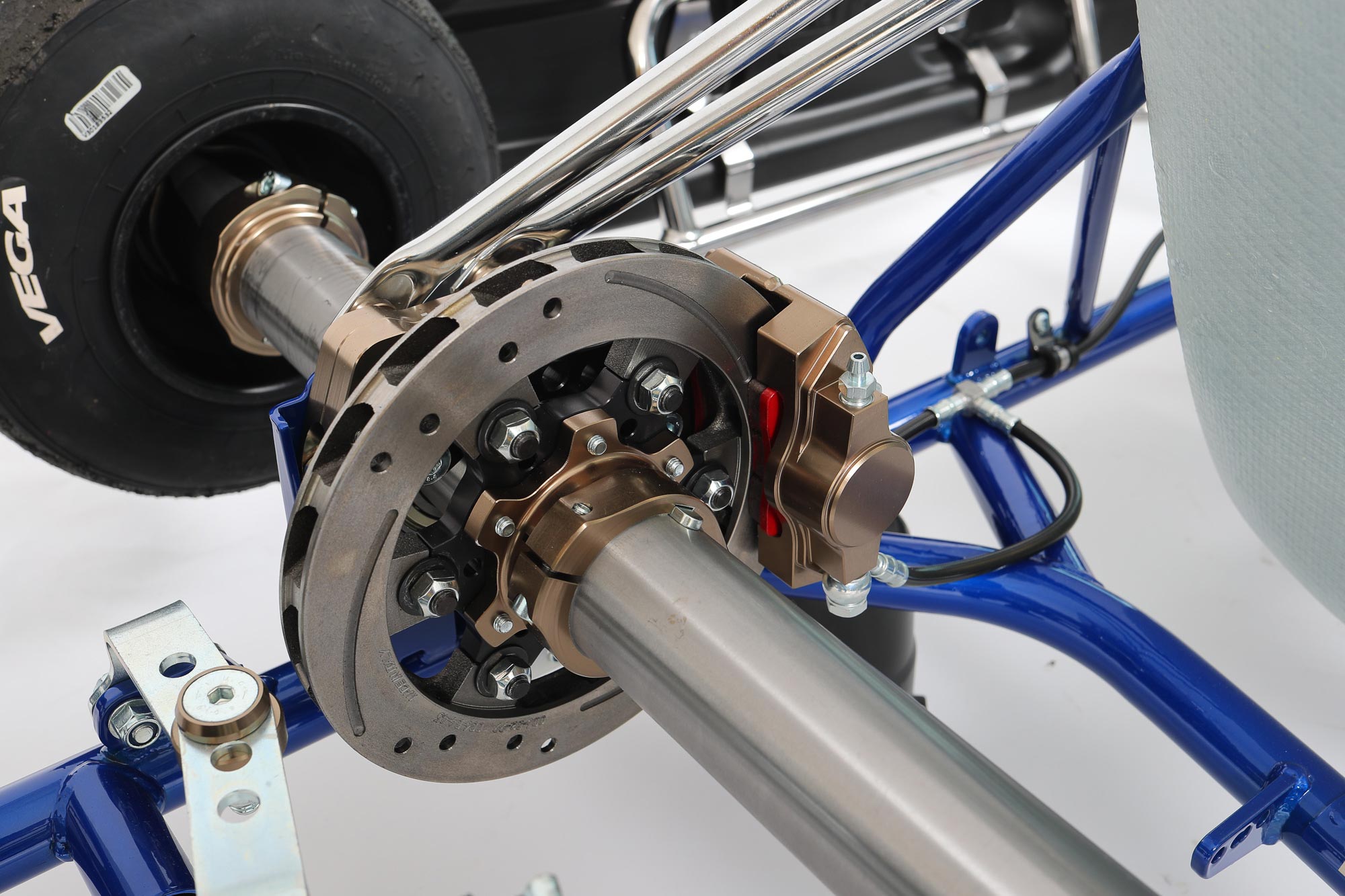

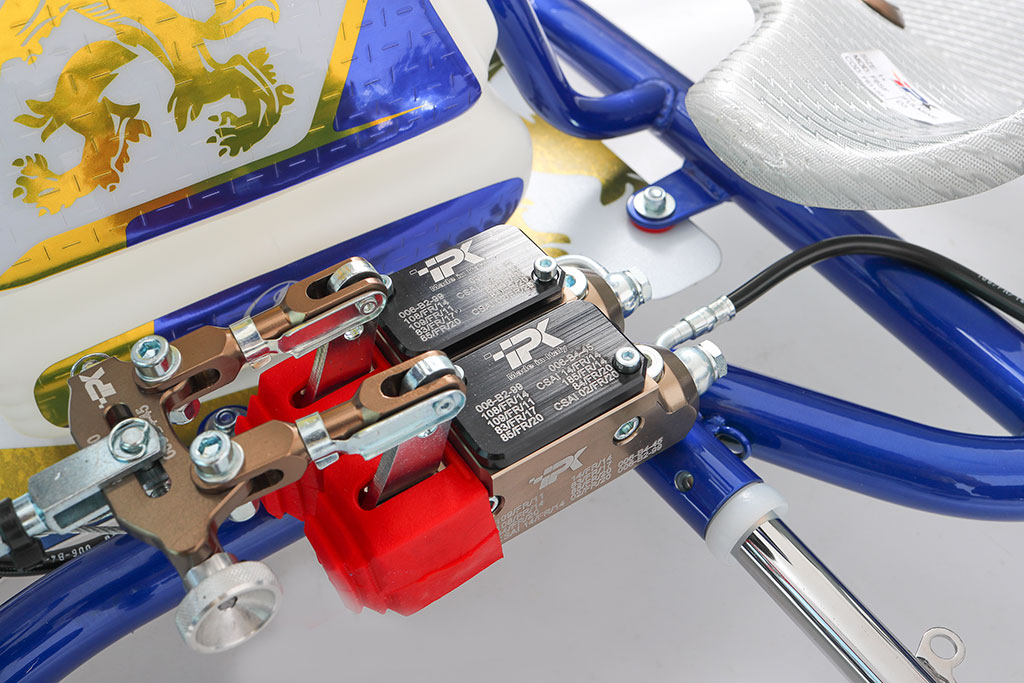

IPKarting, with the new 2018-2020 homologation, has reviewed and improved its rear braking system dedicated to single-speed karts. The new model is called RBS.V2 and, together with STR.V2 designed for the categories with change of gears, represents the maximum development of IPK accessories.

The new system equips Praga Karts OK1 and Formula K chassis.

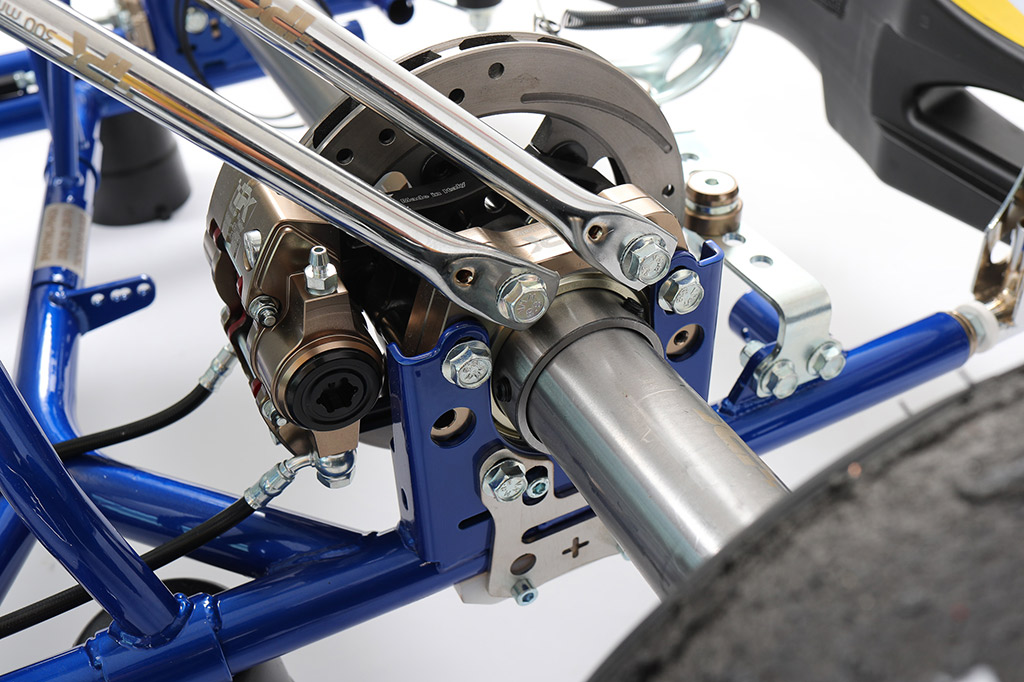

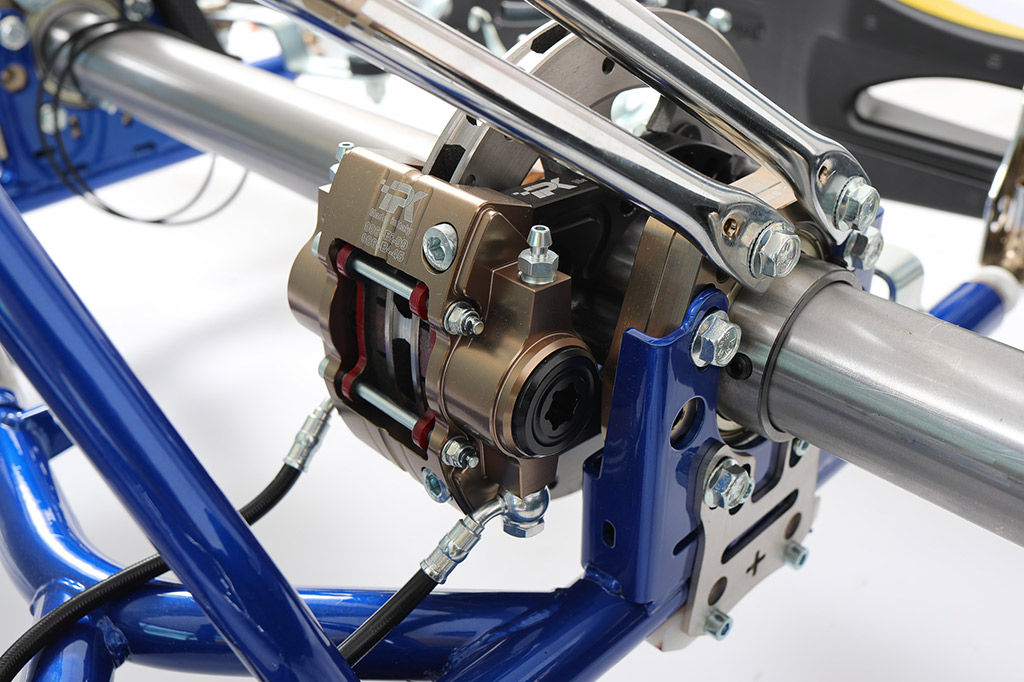

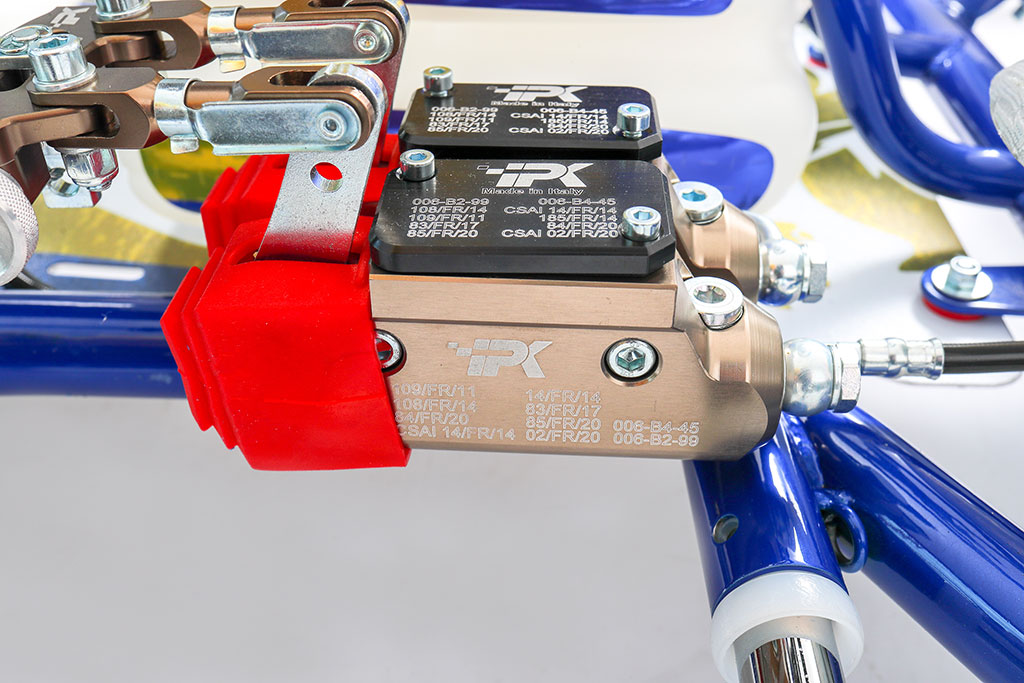

BRAKE CALIPER

The brake caliper, faithful to the IPK philosophy according to which accessories installed on chassis must be carved from a solid material, cared for with the minimum amount of details and is also a radial attachment. To push the brake pads against the disc, two pistons are used: their diameter is 28 mm. On the side leaning against the pads, the two pistons have undergone a process aimed at improving their cooling while optimizing the cleaning of powder generated by the pads.

Compared to the previous homologation, the new caliper is optimized in its shape. Objective: not only to improve cooling, but also to achieve a significant reduction in total weight. Furthermore, IPK technicians have reduced the bending points to increase their durability.

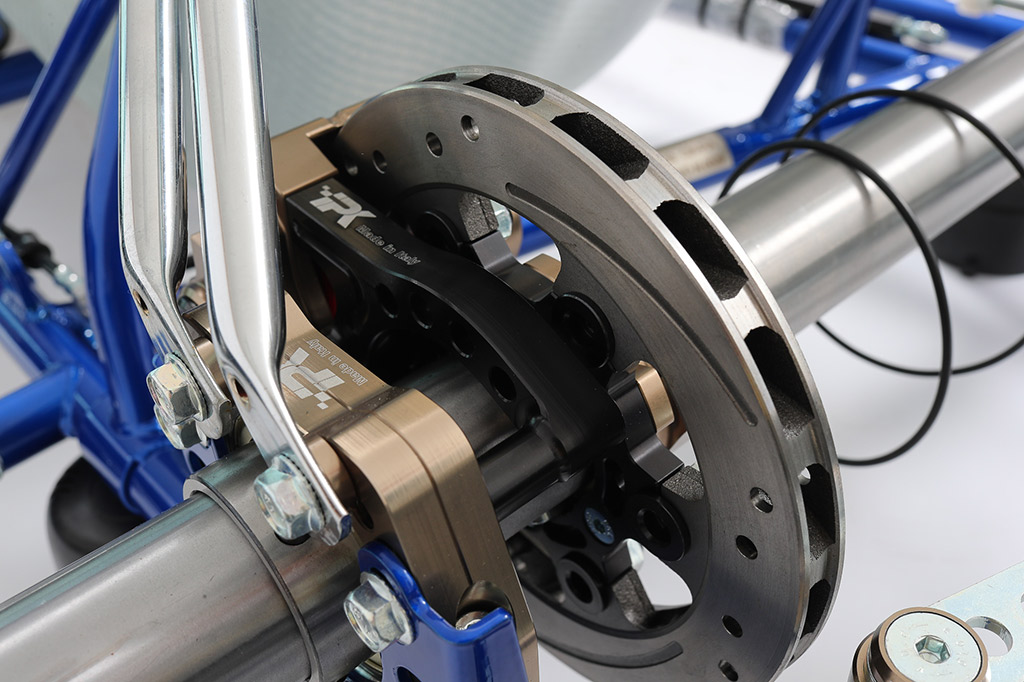

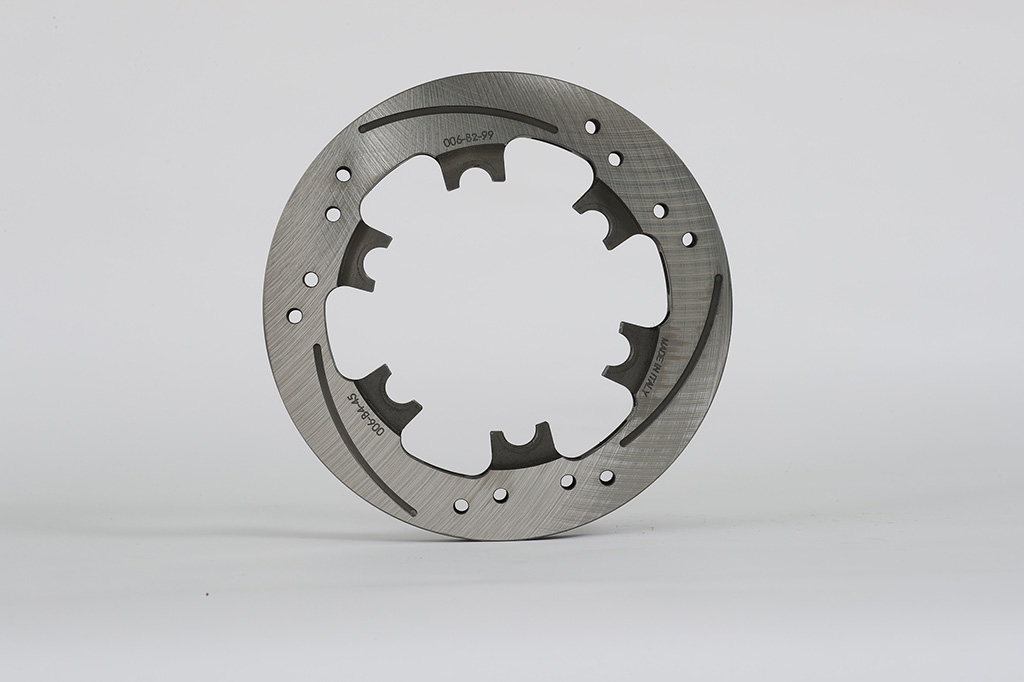

BRAKE DISC

The brake disc is floating and self-ventilating. The RBS.V2 and STR.V2 systems have the possibility to mount discs of two different diameters: 187 mm and 195 mm, the 195mm is the optional larger size.

Compared to the prior homologation, the rear disc has a thickness of 16 mm, that is 1 mm of more material added to the right and left walls to increase its durability.

TYPE OF PADS

With the 2018-2020 homologation, IPK has introduced a new model of pad, with a friction material which adapts to the new generation system with a much-improved method.

In total there are four available pads that allow the improved braking system according to the style of the different drivers or of the grip provided by the asphalt each individual time.

SOFT: identified by the color green, it has the most forgiving friction material. It allows for more aggressive braking with the least amount of pressure on the brake pedal. At the same time, the use of the softer pads is faster.

MEDIUM-SOFT: recognizable by the color red, it is the new pad specifically designed for the latest homologation braking system. Mounted as the standard on the chassis of the IPK group, it is considered the best choice by the drivers of the official Racing Teams.

MEDIUM: of black color, it has a friction material whose hardness is placed halfway between the medium-soft and the hardest pads. These pads allow the driver immediate braking, yet modular according to the curve that the driver has to take on.

HARD: composed of the hardest friction material, it is the most suitable choice for drivers who seek a gentle braking or for those who exert a lot of pressure on the brake pedal. The pads are easily recognizable by their blue color and their durability is greater when compared to the black, red and green pads.

MASTER CYLINDER

The master cylinder has the task of transforming the thrust force imparted on the brake pedal with hydraulic pressure. This element is obtained from solid aluminum and worked through computer numerical control machinery.

Inside the cylinder operates a small 19 mm piston, while above, we find the basin for the “stroke recovery” which job is to guarantee a consistent stroke of the brake pedal even with the wear of the pads. The pump is externally mounted, and titanium-gold anodized like the other chassis’ accessories.

The oil contained in the system is the Xeramic brake fluid dot 5.1, which guarantees high performance and durable use of the system. The same master cylinder is supplied for the braking systems RBS.V2 and STR.V2.